In modern materials science, mechanical engineering, lubricant development, and product quality control, friction and wear testing machines are essential laboratory equipment. They are used to evaluate the friction behavior and wear characteristics of materials, coatings, lubricants, and other substances under various loads, motion states, and environmental conditions. Among these, load-controlled friction and wear testing machines are designed to precisely control the load applied between the contacting surfaces of a specimen. They can simulate real-world friction and wear processes while providing accurate quantitative data on key parameters such as the coefficient of friction, wear rate, and wear volume. Essentially, these machines are core analytical tools for tribology research and material performance evaluation.

Friction and wear are fundamental topics in tribology, the study of friction forces, wear mechanisms, and lubrication strategies during relative motion between surfaces. Laboratory testing using friction and wear machines allows quantification of these phenomena, providing critical data for industrial design, material optimization, and reliability prediction.

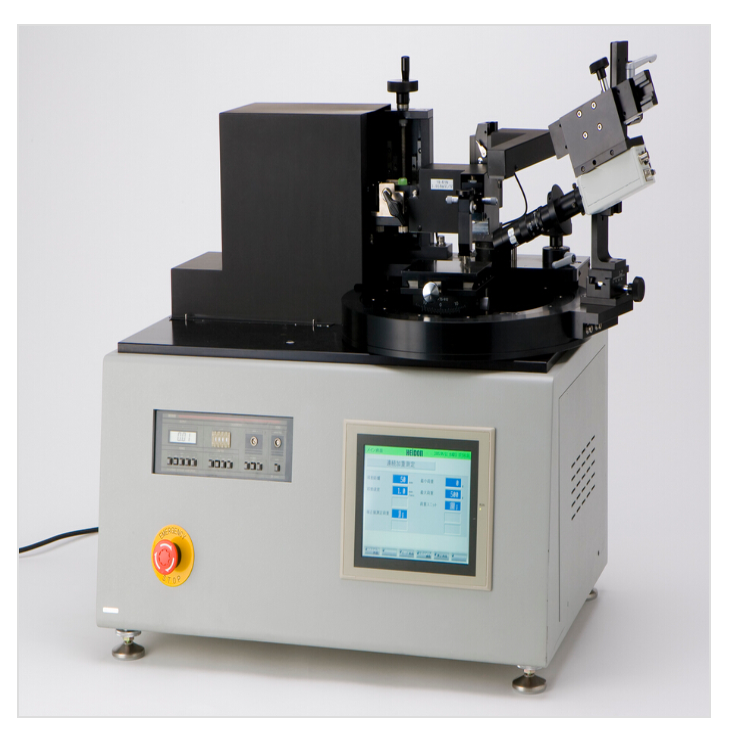

A friction and wear testing machine is a device used to evaluate the frictional behavior and wear performance of materials in contact. The machine generates relative motion between two or more material samples under specified load, speed, and control conditions while measuring parameters such as friction force, wear volume, and wear rate. It is commonly used to determine the coefficient of friction and observe wear phenomena, making it one of the most widely used tools in tribology research.

Traditional friction and wear testing machines typically consist of:

Specimen clamping system

Friction head

Drive and motion system

Load application system

Measurement and data acquisition system

During testing, the load system applies a predetermined normal force, while the drive system moves the specimen relative to the friction partner. Sensors measure friction forces and wear in real time. The data collected can be used to calculate the coefficient of friction, analyze wear mechanisms, and assess material durability.

Load-controlled machines, as the name suggests, precisely control the force applied between contacting surfaces throughout the test. This allows accurate simulation of real-world conditions, such as those encountered in mechanical transmissions, lubricated interfaces, or wheel-rail contacts. Load control highlights the precision and reliability of modern friction and wear testing technology.

1. Specimen Clamping and Friction Head Module

Specimen clamps: Secure the test samples to maintain stable relative positioning. Different test configurations, such as pin-on-disk or ball-on-disk, require specific fixtures.

Friction head: Comprised of a counterpart material that contacts the sample and moves under the applied load. Common arrangements include ball-on-disk, pin-on-disk, and four-ball configurations.

2. Drive and Motion System

The system provides relative motion between contact surfaces through motors, servo drives, or reciprocating devices. Motion types can include rotational, reciprocating, or combined motion, with adjustable speed, frequency, and trajectory according to test requirements.

3. Load Control System

The core of load-controlled machines: precision load sensors and actuators apply and maintain normal forces on the friction pair. The applied load can be constant, dynamically varying, or follow a predefined curve. Accurate load control directly influences the precision of friction coefficient and wear data.

4. Measurement and Data Acquisition System

Sensors measure variables such as friction force, coefficient of friction, wear volume, and contact temperature. Data acquisition systems collect, display, and record measurements in real time, enabling precise analysis of complex tribological behavior.

Load-controlled friction and wear machines are based on tribological principles, aiming to simulate material behavior under real loads, speeds, and contact conditions while providing reproducible results.

Coefficient of Friction and Load Contro

In standard configurations like pin-on-disk or ball-on-disk, the load is applied via actuators, and the friction force is measured dynamically. This allows precise assessment of load sensitivity and material wear mechanisms.

Wear Volume and Load Relationship

Wear refers to material loss caused by friction and load. Load-controlled machines can vary the normal load and measure corresponding wear depth or volume, providing insights into material wear resistance at different stress levels. Typically, higher loads result in greater wear, helping researchers understand wear mechanisms and optimize materials or lubricants.

1. Evaluation of Material Friction Performance

The primary function is to measure material friction behavior, including changes in friction coefficient, peak friction, and steady-state regions. Friction curves can reveal mechanisms such as transition from static to dynamic friction, abrasive effects, and lubrication-induced friction reduction.

2. Evaluation of Wear Performance

Wear testing quantifies material loss under friction, impact, or contact loads. Load-controlled machines measure wear volume, mass loss, or scratch length to analyze wear mechanisms:

Adhesive wear: Local bonding and tearing between contacting surfaces.

Abrasive wear: Hard particles scraping the surface.

Fatigue wear: Surface material spalling under repeated load.

Wear analysis is supported by examining wear track morphology, debris, and mechanical property changes.

3. Lubricant Performance Evaluation

The machines simulate friction under lubricated conditions, evaluating lubricants’ ability to reduce friction and wear. Tests such as four-ball wear experiments assess lubricants’ anti-wear and extreme pressure properties under standardized conditions.

4. Material/Coating Development and Quality Control

New materials, surface treatments, or coatings can be tested under controlled load and environmental conditions (temperature, humidity) to evaluate wear resistance and friction performance. Load-controlled machines are essential for material selection, process optimization, and lifespan assessment. They also support batch quality control by detecting inconsistencies in friction and wear data.

5. Simulation of Environmental and Loading Conditions

Advanced machines allow testing under controlled temperature, lubrication, and environmental conditions, replicating real-world service environments for more accurate tribological assessment.

Load-controlled machines can perform tests according to international and industry standards:

ASTM G99: Pin-on-disk and ball-on-disk friction and wear testing.

ASTM D4172 / D2266: Lubricant anti-wear evaluation using four-ball testing.

ISO, GB, and other standards: Linear reciprocating wear tests and additional tribology protocols.

Standards ensure test comparability, repeatability, and compatibility with industry databases.

1. Materials Science and Engineering R&D

Evaluate durability, friction stability, and lifespan under realistic conditions, providing experimental support for material selection and design.

2. Lubricant and Oil Development

Assess anti-wear performance and friction reduction of lubricants for engines, hydraulic systems, and other industrial applications.

3. Automotive, Mechanical, and Aerospace Components

Simulate and evaluate the service performance of frictional components like bearings, gears, and engine parts under laboratory conditions.

4. Electrical and Microelectronics

Micro-scale friction testing for MEMS and micro-contact systems, influencing device reliability and lifespan.

Comprehensive Load Simulation: Real-world systems involve multi-level loads, high-cycle stresses, and coupled physical fields. Future machines must provide precise multi-dimensional control.

Data Analysis and Intelligence: Advanced data analytics, machine learning, and predictive modeling are increasingly important for large datasets generated during testing.

Micro/Nano Materials and Complex Coatings: Testing thin films, composites, and micro-scale materials requires higher sensor sensitivity and precise control.

In summary, load-controlled friction and wear testing machines are precision tribology instruments that enable detailed evaluation of materials, lubricants, and coatings under controlled loads and motion parameters. Combining mechanical, electronic, and data acquisition technologies, these machines are essential for material R&D, lubricant evaluation, engineering component testing, and quality control. Through precise load control, friction measurement, and standardized testing, they provide a solid data foundation for optimizing material and product performance, improving reliability, and advancing tribology research.

Prev:What is the difference between abrasion test and pilling test?

Next:No more