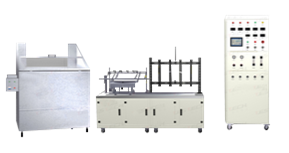

Wire and cable fire-resistant impact spray testing integrated machine

Wires and cables that are difficult to ignite and have the ability to prevent or delay flame propagation usually refer to wires and cables that can pass the GB/T18380.3 (equivalent to IEC60332-3) test; This wire and cable fire resistance impact tester is developed and produced according to the IEC 60331-12 BS6387-2013 standard, used for testing the integrity of the circuit under the condition of flame temperature not lower than 830 ℃ and certain impact vibration. Can test the A, B, C, and D level flame retardant performance of cables

Applicable scope:

This tester can be used to test the flame retardancy, impact resistance, and spray test of wires and cables against fire, to see if the circuit can still maintain integrity.

Reference standard:

IEC 60331 Part 12 Tests for cables and optical cables under fire conditions - Line integrity - Part 12: Test apparatus - Impact combustion at least at 830 ° C

IEC 60331 Part 31 Testing of cables under fire conditions - Line integrity - Part 31: Procedures and requirements - Cables with rated voltages of 0.6/1.0kV and below

IEC 60331-1 Line integrity testing of cables under flame conditions - Part 1: Test method for cables with rated voltage of 0.6/1.0kV and below, total diameter greater than 20mm, under impact flame at a temperature not lower than 830 ℃

BS6387-2013 Fire resistance test method for maintaining line integrity of cables under flame conditions

IEC 60331-2 Line integrity testing of cables under flame conditions - Part 2: Test method for cables with rated voltage up to and including 0.6/1.0 KV and full diameter not exceeding 20 mm under impact flame at a temperature not lower than 830 ° C

Product features:

1. Control cabinet parameters:

Equipped with dual flow meters and pressure regulation.

Automatic control of the experimental process.

Equipped with intelligent detection function, it automatically alarms and turns off the fire source when a short circuit occurs in the sample during the testing process.

Display: Touch screen, displaying temperature curve

Time timer: 0-99 hours, 99 minutes, and 99 seconds

Control box size: 650 (D) X400 (W) X1200 (H)

Load: The test voltage is adjustable from 0 to 600V;

Load current range: 0.1~3A, test current can be adjusted according to standard requirements, but protection is provided if it is greater than 3A;

The load capacity should ensure that the test sample can continue to be tested even when the test current approaches 3A. It can also be applied to the load requirements of spray testing and hammer impact testing

2. Requirements for fire resistance testing equipment:

The burner has a nozzle with a length of 500mm and a width of 15mm. There are three rows of staggered small holes on the nozzle, with a hole radius of 1.32mm and a hole spacing of 3.2mm. Equipped with Venturi mixer;

The testing ladder for installing cables is fastened to the supporting steel base; During the testing process, the vertical components on both sides of the testing ladder can be adjusted according to different cable size requirements (testing frame length: 1200mm, height: 60mm, total weight: 18 ± 1kg);

The inner diameter of the metal ring is approximately 150mm;

Equipped with temperature measuring device (K-type thermocouple with a diameter less than 2mm, 75mm away from the flame mouth);

The front end of the burner nozzle should be no less than 200MM from the bottom of the box, and no less than 500MM from the wall of the box;

According to the test level, the flame temperature can be adjusted: 600~1000 ° (A level 650 °, B level 750 °, C and D level 950 °)

The horizontal axis of the burner is 40-60mm away from the center of the test cable, and the vertical axis of the burner is 100-120mm away from the vertical axis of the sample cable

Provide 5 metal rings with an inner diameter of approximately 150 mm as required by the standard, and the distance between the metal rings can be freely adjusted to facilitate the fixation and support of the test piece.

Stainless steel sample holder, capable of supporting 30kg

3. Hammer test device section:

Stainless steel bracket impact structure; Painting treatment of the box body;

2. Independent motor impact control box;

3. A rough round steel rod with a hammering cone of ¥ 25 and a length of 600.

4. The hammer hammer falls freely at an angle of 60 degrees.

5. The electric motor drives the rod hammer to perform a periodic impact action.

6. Hammering cycle (time): 10~999S (adjustable, standard requirement of 30 ± 2S/time)

7. Total test time: 0-9999S

8. Belt burner (same as spray test) (shared with refractory combustion test bench)

9. Test temperature 600-1000 ° C (A grade 650 ° C, B grade 750 ° C, D grade 950 ° C)

10. The diameter of the temperature measuring thermocouple is less than ¥ 2mm. (Shared with refractory combustion test bench)

11. During the experiment, a current of 0.25A was applied to each phase of the cable.

4. Spray test device (optional):

Burners using propane or natural gas, using an integral 400mm long strip burner.

The combustion test temperature is 650 ± 40 ° C.

Use thermocouples with a diameter not greater than ¥ 2 for temperature measurement.

The water supply pressure of the sprinkler head is 250-350Kpa, and the water spray rate on the test sample is about 0.25-0.3L/S.m2.

The length of the test sample is approximately 400mm.

During the experiment, the test cable is energized through an isolation transformer and connected to a 3A fuse or circuit breaker, with on/off signal lights indicating each phase cable.

Technical parameters:

Size: 1600 (W) x 850 (D) x 1900 (H) mm

Console size: 600 (W) x 750 (D) x 1200 (H) mm

Power supply: AC 380V 3-phase, 50/60Hz, 30A

Weight: 100Kg

Flame temperature: 600-1000 ℃ (adjustable)

Instructions: Provided

Exhaust: minimum 15m3/min

Tools: vacuum cleaner, computer, compressed gas, propane gas

Prev: Surface tension meter