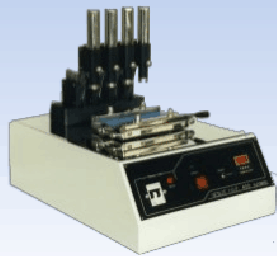

Veslic four station wear resistance tester

The Veslic four station wear resistance tester is used to measure the color fastness to friction of dry/wet fabrics. This device has four workstations, each of which can independently load 500g or 1000g. After the sample is clamped and fixed on the vibration testing bed, a 25% tension can be applied. Each workstation is equipped with adjustable brackets to place detection felt pads, which can accommodate rubber pads of the same size. Felt mats are used for color fastness and damage assessment. Dry and wet testing can be performed (usually using deionized water or synthetic sweat). The testing samples and test felt components are evaluated for color changes by comparing them with the standard gray standard under a standard multi light source color light box. Using rubber pads instead of felt pieces can simulate the friction between the sole and the leather at the front of the shoe, similar to the wearer crossing their legs and placing one shoe on another.

Applicable scope:

The Veslic tester is used to evaluate the color fastness (similar to friction fading) of friction tests on materials such as leather, fabric, ethylene, stitching seams, plastics, etc., to assess the degree of damage to the surface of the sample, and to determine the amount of color transferred from the sample to the friction pad. The wear resistance of the upper material of the sole can also be tested using this instrument. This type of test can be conducted by replacing the felt pad with a small irregular rubber friction pad.

Compliant with standards:

EN ISO 20344: 7.3 Personal protective equipment - Test methods for footwear

DIN 53339 Testing of leather - Method for determining the wear resistance of dyeing and finishing

BS EN ISO 11640 Leather - Tests for color fastness - Color fastness to cyclic reciprocating friction

UNI EN ISO 11640 Leather - Tests for color fastness - Color fastness to cyclic reciprocating friction

DIN 53340 Testing of Leather - Determination of Durable Wrinkle Performance of Semi Flexible Leather

NF EN ISO 5402 Leather - Determination of flexural resistance - Deflectometer method

JIS K 6545 Test Method for Bending Resistance of Light Leather and Surface Decorative Materials

I. U.F 450, I U F 454, I U. F 458, IUP 450, SLF 450

Structural specifications:

Steel plate bearing structure coated with acid resistant epoxy resin

Non lubrication motion device

18/8 stainless steel horizontal surface with fixture

Sample extension 10% system

Felt clamp with a load of 500gr and a size of 15 × 15mm

An additional weight of 1000g in total

Sports space greater than 35mm

Brass and stainless steel brackets

Anti condensation steel shield self-aligning bearing

Control panel:

Main switch

Fastener self-adjusting axis button

6-digit and automatic zero pulse electronic counter editor