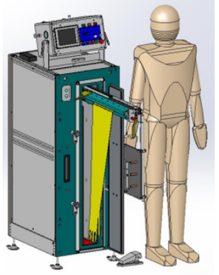

Glove integrity tester

The glove integrity tester is a non-destructive leak detection system designed for personal protective equipment such as gloves.

The glove integrity tester is designed according to standard regulations to replace airtightness testing. This instrument can quickly and easily quantify the level of glove sealing to measure leakage values.

Ergonomic and user-friendly programming and operation:

The large high-resolution touch screen provides a clear user interface and allows for quick and intuitive understanding of the instrument.

The operator of the glove integrity tester is based on vacuum leakage test:

This measurement method is ideal for checking the integrity of personal protective equipment such as gloves. This method involves generating a vacuum in the chamber where the product is placed, isolating it, and measuring the pressure changes in the gloves.

This change is directly related to the degree of completeness of the gloves.

Product application:

The glove integrity tester is mainly used to test the integrity of personal protective equipment such as gloves.

Product operation:

-The operator puts on gloves and closes the door

-Automatic start of cycle

-Establish a vacuum in the testing chamber and stabilize it

-Measure the pressure changes inside the gloves over a certain period of time

-Test room returns to atmospheric pressure

-The result shows: green light: on, red light: failed

-The measured values can be output in Excel or PDF format

Product features:

Non destructive testing

Speed: Large size samples require very little time for inspection

100% testing may target sensitive or problematic batches

Calibration reference glove certification measurement

Verification measurement, real-time verification of the measurement chain

Test bench validation, certification qualifications (IQ, OQ, PQ), transposition standards

Physical measurement of tightness

Correct sealing value

The test results are not affected by the operator, alerts, etc.

Assisted by ASC instrument experts in execution

FAT, SAT, IQ, OQ, PQ, transposition standards

Technical parameters:

Dimensions: 495 x 1687 x 656 mm (w x d x h)

Weight: 350kg

Standard room size (large packaging bag size): 1018 x 125 x 638 mm

Communication: Graphics, 5.7 "touch screen, status lights

Power supply: 24V DC/5 A (adapter provided)

Air supply: clean and dry air, quality in accordance with ISO 8573-1-100 and 600 kPa

Operating temperature:+15 ° C to+25 ° C

Storage temperature: 0 ° C to 60 ° C

Standard test pressure: -10KPa~-60KPa, mainly depending on customer product specifications

Prev: Fire contact heat transfer tester for protective clothing