Abrasion is just one aspect of wear and is the rubbing away of the component fibres and yarns of the fabric. It is a series of repeated applications of stress; therefore a capacity to absorb punishment is required to the fibres. Inherent fibre properties such as work of rupture may give a high resistance to abrasion.

Theory :

A number of important points require consideration before abrasion resistance tests are carried out. The choice of the method may be governed by the type of apparatus available, the precision demanded and so forth. Some of the more important points are condition of the specimen, choice of testing instrument, choice of abrasive motion, direction of abrasion, choice of abradant, backing the specimen, cleanliness of the specimen and instrument, tension on the specimen, pressure between abradant and specimen, end-point of the test etc. Now there are various abrasion resistance testing instruments available for example, the WIRA abrasion tester, the LIRA abrasion tester, the Taber abraser, the Shiefer machine, the Wyzenbeek abrasion tester, the Stoll universal wear tester, the LINRA wear tester, the BFT abrasion tester etc. The abrasion tester we used here is made by James H. Heal & Co. Ltd, Halifax, England. In this instrument abrasion surfaces wrapping by sand paper are used to abrade the fabric samples. A counter is used to count the no. of abrasion. This is an electrical tester.

Apparatus :

Martindale Abrasion and Pilling Tester

Technical Parameters:

1.Test positions: 9;

2.Count range: 0~999999;

3.Maximum stroke: horizontal 60.5±0.5mm, longitudinal 24±0.5mm;

4.Weight of pressurized materials:

a.Clamp holder assembly: 200±1g

b.Loading pieces for smaller piece: 395±2g

c.Loading pieces for larger piece: 594±2g

d.Stainless steel piece: 260±1g

5.Additional loading weight valid abradent diameter:

Type A 200g(1.96N) Pressure(9KPa) ¢28.8-0.084mm

Type B 155g(1.52N) Pressure (12KPa) ¢90-0.10mm

6.The relative speed with Clamp holder and Abrading table: 20-70r/min(Adjustable);

7.Weight of ample loading hammer: 2385±10g.

Procedure :

At first cut the fabric into 4 pieces according to the measurement of the instrument.

Weigh these 4 pieces of fabric samples.

Now place these samples in the instrument under a certain load as supplied in the instrument.

Now start the machine and observe the counter of abrasion no.

After an abrasion of 200 bring out the first sample and weigh it.

After an abrasion of 300 bring out the second sample and weigh it.

Similarly after abrasion of 400 and 500 bring out the third and fourth sample and take their weight.

Now put the weights before and after abrasions in a table and find out their wear index.

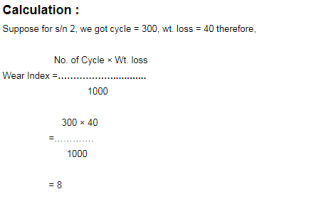

Result :

Wear Index for 200 cycle = 6

Wear Index for 300 cycle = 8

Wear Index for 400 cycle = 14 &

Wear Index for 500 cycle = 34.